The Bently Nevada 3500 Datasheet is an essential document for anyone involved in the monitoring and protection of critical machinery. This detailed resource provides comprehensive specifications and operational information for the Bently Nevada 3500 series of machinery monitoring systems, offering a gateway to understanding how these sophisticated systems ensure the reliability and longevity of industrial assets.

Understanding the Power of the Bently Nevada 3500 Datasheet

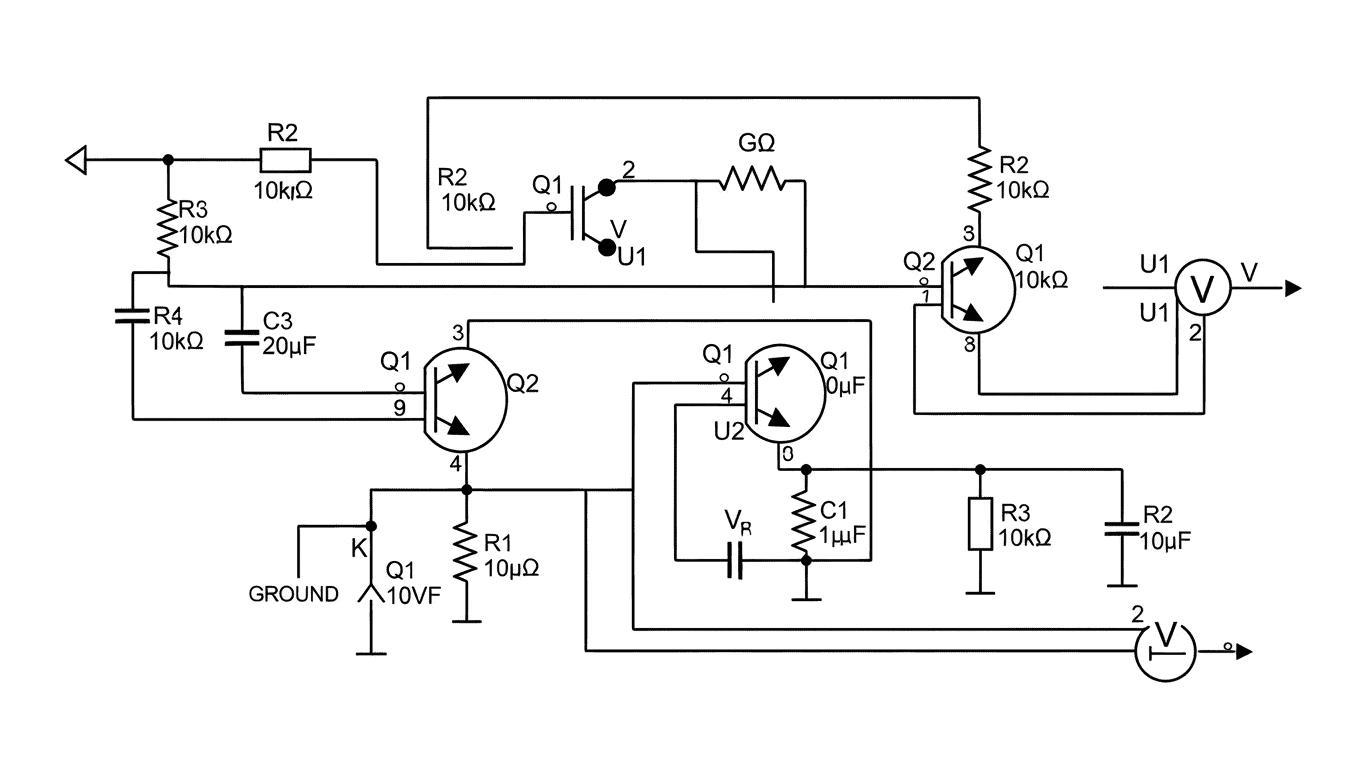

At its core, the Bently Nevada 3500 Datasheet is a technical blueprint for a highly advanced machinery health monitoring system. It details the various components, their capabilities, and how they work together to detect and analyze potential problems within rotating equipment such as turbines, compressors, and pumps. This documentation is not just a collection of numbers; it's a guide to safeguarding your most valuable industrial assets from unexpected failures. The importance of thoroughly understanding these datasheets cannot be overstated , as it directly impacts the effectiveness of your predictive maintenance strategies and the overall operational safety of your facility.

These datasheets serve multiple crucial purposes within an industrial setting. For engineers and technicians, they are the primary reference for selecting the right hardware configuration for a specific application, understanding sensor types, signal processing capabilities, and the system's response to various machine conditions. The Bently Nevada 3500 series is known for its modularity, allowing for tailored solutions, and the datasheet outlines these options clearly.

Here's a glimpse of what you'll find within a typical Bently Nevada 3500 Datasheet:

- System overview and architecture

- Detailed specifications for each module (e.g., power supply, processor, I/O modules)

- Sensor compatibility and performance characteristics

- Alarm and protection functionalities

- Communication protocols and integration capabilities

Furthermore, the datasheets often include performance graphs and environmental operating conditions. This detailed information is vital for:

- Proper system installation and setup.

- Troubleshooting any operational issues that may arise.

- Performing regular maintenance and calibration.

- Ensuring compliance with industry standards and regulations.

For a clear comparison of different system configurations, a datasheet might present information in a tabular format, similar to this simplified example:

| Module Type | Description | Key Features |

|---|---|---|

| 3500/20 Power Monitor | Provides power to system modules | Redundant power inputs, diagnostic capabilities |

| 3500/40M Proximity Monitor | Measures shaft displacement | Multiple input channels, various measurement ranges |

| 3500/45 Tachometer Module | Monitors shaft speed and position | Speed detection, phase reference capabilities |

By consulting the Bently Nevada 3500 Datasheet, you gain the knowledge to configure, operate, and maintain your machinery monitoring systems with confidence, ensuring the continuous and safe operation of your critical assets.

To fully leverage the capabilities of your Bently Nevada 3500 system, we strongly encourage you to refer to the official Bently Nevada 3500 Datasheet. This document is your definitive guide to understanding and utilizing the full potential of your machinery monitoring solution.