The Bently Nevada System 1 Architecture Datasheet is a critical document for anyone involved in the maintenance and monitoring of industrial machinery. This comprehensive resource provides a detailed overview of the hardware and software components that form the backbone of Bently Nevada's renowned condition monitoring solutions. Understanding the information within the Bently Nevada System 1 Architecture Datasheet is key to effectively implementing, configuring, and troubleshooting these powerful systems, ultimately ensuring the reliable operation of your most vital assets.

Demystifying the Bently Nevada System 1 Architecture Datasheet

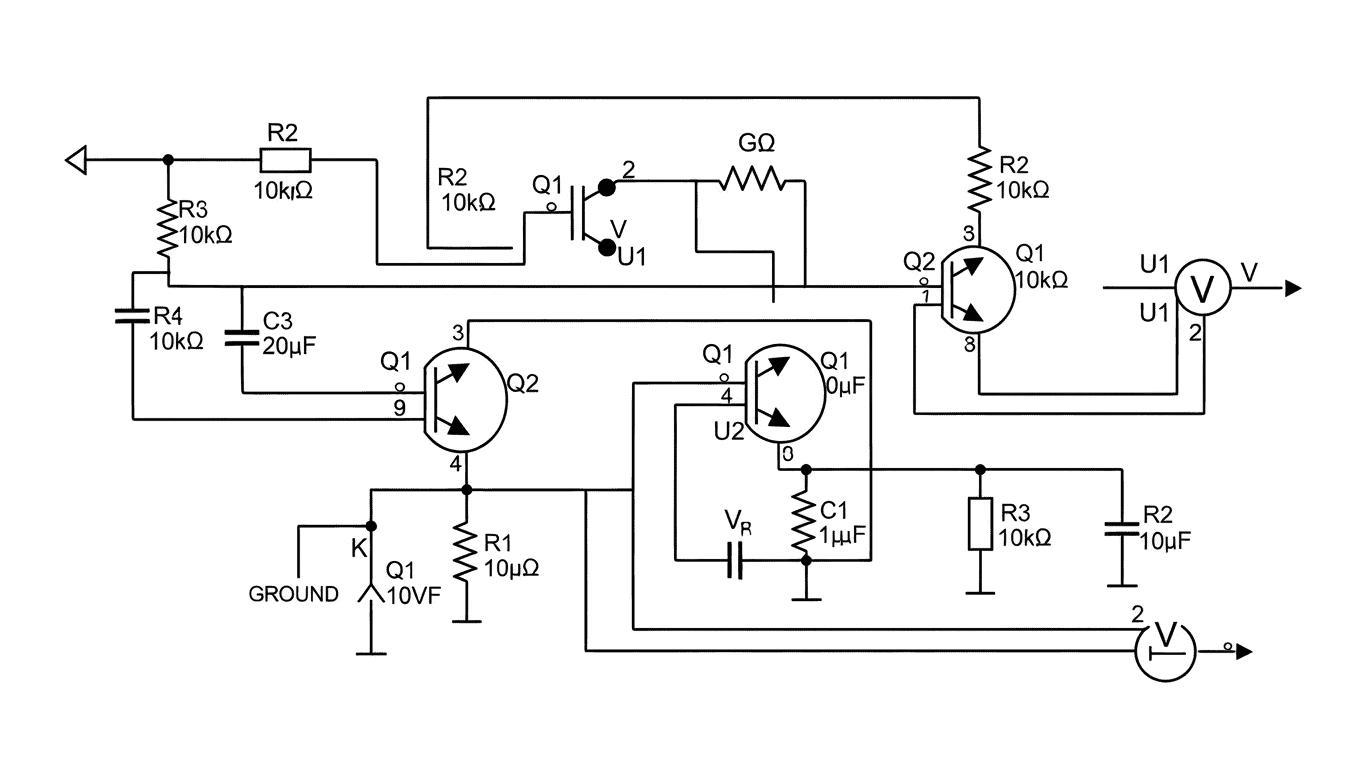

At its core, the Bently Nevada System 1 Architecture Datasheet serves as a blueprint for the entire System 1 platform. It outlines the various modules, their interconnections, and the flow of data from the machinery sensors all the way to the user interface. Think of it as the instruction manual and components list for a sophisticated diagnostic system. It details the hardware units responsible for acquiring vibration, temperature, and other critical process data, as well as the software that processes, analyzes, and presents this information in an actionable format. This includes information on:

- Hardware components such as proximity probes, accelerometers, and velocity sensors.

- Data acquisition modules and their specifications.

- Communication protocols used within the system.

- Server and client workstation requirements.

- Network topology and connectivity options.

The practical application of the Bently Nevada System 1 Architecture Datasheet is vast. For maintenance teams, it provides the necessary understanding to correctly install and configure the system for specific machinery types and operating conditions. Reliability engineers can leverage it to design robust monitoring strategies, ensuring that all critical parameters are captured and analyzed. Furthermore, during troubleshooting scenarios, the datasheet becomes an invaluable reference for identifying potential hardware failures or configuration issues. The ability to accurately interpret and apply the information found in the Bently Nevada System 1 Architecture Datasheet is paramount for maximizing the effectiveness of your machine condition monitoring program and preventing costly downtime.

To further illustrate the system's structure, consider a simplified representation of its data flow:

| Stage | Key Components | Function |

|---|---|---|

| Data Acquisition | Probes, Accelerometers, Data Acquisition Modules (e.g., 3500 Series) | Collect raw sensor data from machinery. |

| Data Processing | System 1 Software (Server) | Digitizes, filters, and performs initial analysis on incoming data. |

| Analysis & Visualization | System 1 Software (Client) | Presents data through trends, alarms, spectral analysis, and reports. |

| Alerting & Action | System 1 Software, Alarm outputs | Notifies personnel of potential issues and triggers corrective actions. |

Understanding this flow, as detailed in the Bently Nevada System 1 Architecture Datasheet, allows for optimized system performance and faster response times to potential machine problems. It's not just about knowing the parts; it's about understanding how they work together to safeguard your operations.

To gain a complete and in-depth understanding of your Bently Nevada System 1 setup, we strongly recommend consulting the official Bently Nevada System 1 Architecture Datasheet. This document is the definitive source for all technical specifications and architectural details.